USA Acrylic Glitter Sheet Shipment Factory Export & Packaging

Full-Container Acrylic Glitter Sheet Order for the U.S. Market

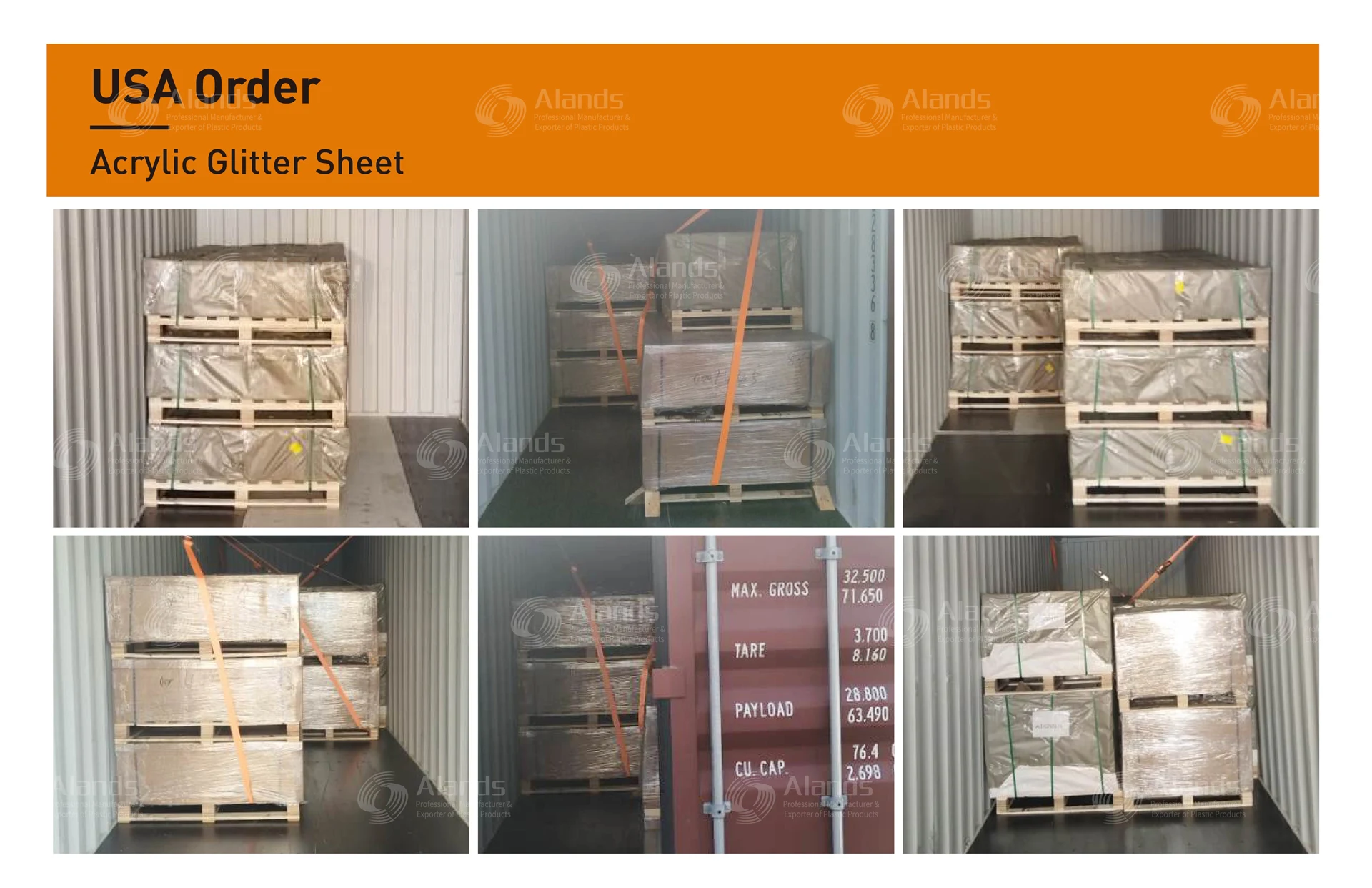

These photos were taken during the loading of a recent Acrylic Glitter Sheet order for our U.S. customer, recorded at our factory warehouse and inside the container.

This shipment was arranged as a full-container order, produced and packed in a single batch. All sheets were sorted by size and thickness before loading to ensure consistency across the entire shipment. The pallets were prepared in advance so that the boards could be loaded efficiently while maintaining stability during long-distance sea transportation.

For U.S. customers, especially those using acrylic sheets for fabrication and retail display, consistency and surface condition are critical. This shipment was prepared with that in mind from the very beginning.

Individual Film Protection and Reinforced Export Packaging

Every acrylic glitter sheet in this order was individually covered with protective film. The film protects the glitter surface from scratches, friction marks, and dust during handling, loading, and unloading.

In addition to surface film, the sheets were fully palletized and wrapped, with reinforced strapping to keep each stack tight and stable. The pallet structure helps distribute weight evenly and prevents pressure damage to the lower sheets. This type of packaging is our standard solution for acrylic glitter sheets shipped overseas, especially for routes with longer transit times.

For us, acrylic glitter sheets are not just decorative materials—they are appearance-driven products, and surface protection is treated as a priority, not an option.

Secure Pallet Stacking and Container Fixing

During container loading, all pallets were placed with controlled spacing and aligned carefully along the container floor. Fixing straps were applied inside the container to limit movement during transit, reducing the risk of shifting caused by braking, waves, or container handling.

Stacking height and pallet weight were strictly controlled to ensure that the sheets remain flat and stress-free throughout the journey. Our goal is always the same: when the container door is opened in the U.S., the sheets should look exactly the way they did when they left our factory.

How We Manufacture Acrylic Glitter Sheets for Practical Use

As a manufacturer, we understand that acrylic glitter sheets are selected not only for their visual effect, but also for their processing performance.

Our acrylic glitter sheets are produced using high-quality acrylic material with evenly distributed glitter particles. The surface is smooth and visually consistent, making the sheets suitable for laser cutting, CNC routing, and other fabrication processes. Thickness control and batch consistency are especially important for customers who process large volumes or supply finished products to the retail market.

The sheets in this U.S. order were selected for stable quality, clean surface appearance, and reliable processing performance, which are key factors for repeat orders.

Why Acrylic Glitter Sheets Are Popular in the U.S. Market

From our experience with U.S. customers, acrylic glitter sheets are widely used for:

Retail displays and POP signage

Decorative panels and branded fixtures

Craft fabrication and customized products

Interior decorative elements

Customers value not only the sparkle effect, but also whether the sheets arrive ready to use, without additional cleaning, polishing, or reworking. That is why packaging, pallet stability, and surface protection are treated as part of the product itself.

Shipment Quality Reflects Manufacturing Standards

We prefer to share real shipment photos because they show more than specifications. Cleanly wrapped pallets, protected surfaces, controlled loading, and secure fixing inside the container all reflect how we handle our products before they leave the factory.

For us, shipment quality is a direct extension of manufacturing quality. Proper packaging and careful loading ensure that acrylic glitter sheets reach the U.S. market in the condition our customers expect—and can rely on for their production and sales.