Acrylic Sheet Yellow – High-Performance Colored Cast Plexiglass Panel

Vibrant yellow acrylic sheet with a smooth finish. Durable, UV-resistant, easy to cut and shape. Perfect for signage, art, displays, and crafts. Various sizes available. Inquire today!

Brand: alands

Origin: Jinan, Shandong, China

Product type: Acrylic Sheet Yellow

Routine size (mm): 1224*2240 or customize

Customization : size, color, thickness, style

MOQ: 1000kg (1ton)

Acrylic Sheet Yellow– High-Performance Colored Cast Plexiglass Panel

Yellow Acrylic Sheet Product Overview

Our yellow acrylic sheet, also known as yellow plexiglass or yellow plastic panel, is a durable, lightweight, and UV-stable material ideal for both indoor and outdoor use. Manufactured using high-quality cast PMMA, it offers excellent clarity, vibrant color consistency, and weather resistance. Suitable for signage, lighting, display, and decorative applications.

Yellow Acrylic Sheet Sizes, Thickness, and Technical Specifications

Standard Sheet Sizes:

1220mm x 2440mm (4ft x 8ft)

2050mm x 3050mm (optional oversized)

Thickness Range: 2mm – 30mm (custom available)

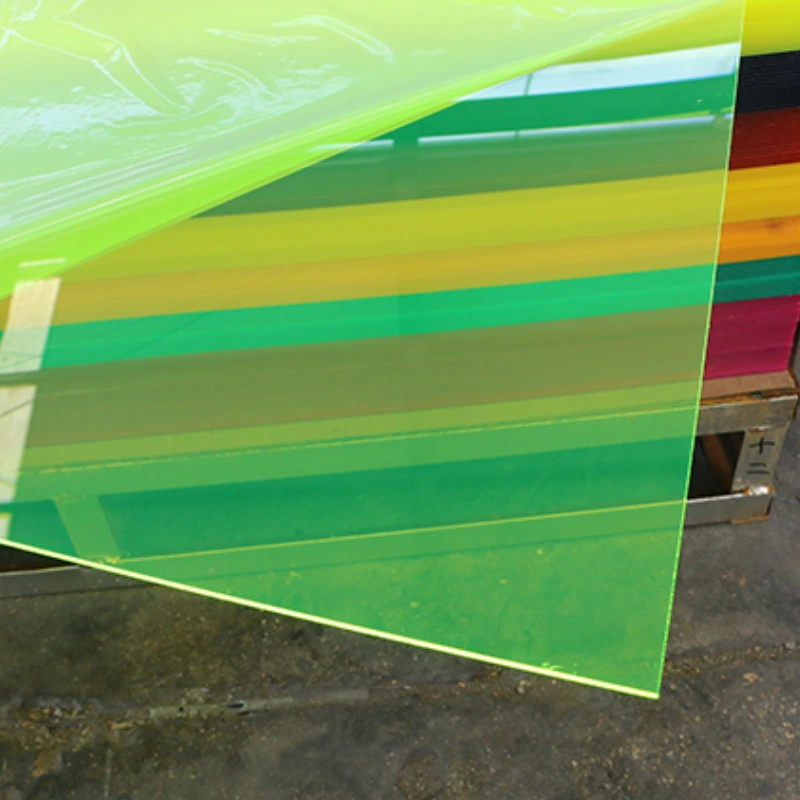

Color Options:

Opaque yellow, translucent yellow, pastel yellow, neon yellow

Pantone color customization supported

Surface Finish: Glossy (default), Matte, or Frosted

Material Type: Cast Acrylic (100% virgin PMMA)

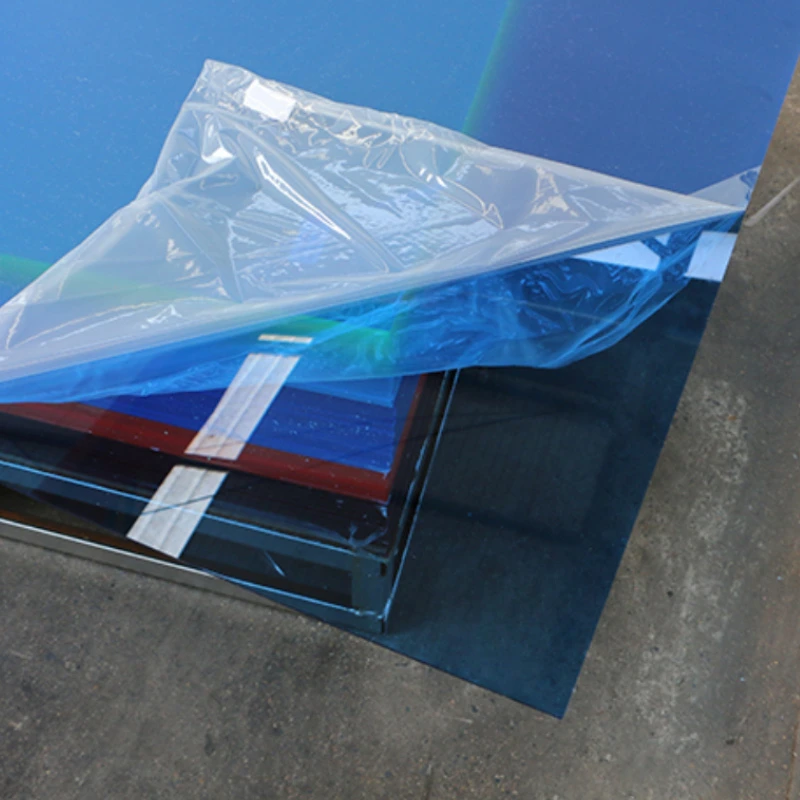

Protective Masking: PE protective film (standard) or Kraft paper (laser-safe)

Sheet Weight: From approx. 7.4kg up to 100kg, depending on thickness

Applications of Yellow Acrylic Sheets in Commercial and Industrial Projects

Yellow acrylic sheets are used in a wide range of sectors where visibility, color, and durability are essential:

Commercial signage and retail branding

Light diffusers in LED lighting panels

Safety signage, barriers, and warning boards

Decorative architectural panels and furniture

POP (Point of Purchase) displays and merchandising units

Laser-cut craft and DIY art projects

Automotive trim or dashboard highlights

Equipment covers and machine guards

Educational materials and learning boards

Trophies, awards, and promotional items

Model making and exhibition prototypes

How to Cut and Process Yellow PMMA Sheets for Fabrication

Our yellow PMMA sheets (cast acrylic) can be easily fabricated with standard plastic processing tools. Depending on project needs:

Laser cutting produces polished, clean edges

CNC routing enables complex patterns and bulk production

Circular and table saws work well for straight-line cuts using fine-toothed blades

Score-and-snap methods apply to thinner sheets under 3mm

Sheets can also be drilled, polished, engraved, bent (with heat), or glued using acrylic-compatible adhesives

All sheets are supplied with masking to protect the surface during handling and fabrication.

Custom Yellow Acrylic Sheet Options from Alands Plastic Co., Ltd.

At Alands, we manufacture and supply custom yellow acrylic sheets tailored to your project requirements. We support:

Color Matching: Solid yellow, translucent, neon, and Pantone-matched tones

Custom Sizing: Cut-to-size service based on your specifications

Custom Thickness: From ultra-thin 2mm to ultra-thick 30mm

Masking Film Options: PE (standard) or kraft paper (recommended for laser processing)

OEM Services: Branding on protective film, private label packaging, and export cartons

Bulk Supply & MOQ: Competitive pricing for large orders; flexible MOQ options for custom runs

Contact our team at info@alandsplastic.com for samples, quotes, or detailed product catalogs.

FAQs – Yellow Acrylic Plastic Sheet

Q1: Is yellow acrylic suitable for long-term outdoor exposure?

Yes, our yellow acrylic is UV-stabilized and weather-resistant, making it suitable for outdoor use without color fading.

Q2: What’s the difference between translucent and opaque yellow acrylic sheets?

Translucent sheets allow partial light transmission and are suitable for lighting or signage. Opaque sheets block all light and offer solid color coverage.

Q3: Can I order a custom shade of yellow?

Yes, we offer Pantone color matching and custom yellow tones. Minimum order quantities may apply for special colors.

Q4: Do you provide pre-cut or laser-cut services for yellow acrylic panels?

Absolutely. We offer both cut-to-size and advanced fabrication services including laser cutting and CNC routing.

Q5: What is the production lead time for customized yellow plastic sheets?

Lead time typically ranges from 5 to 10 working days depending on quantity, size, and customization complexity.