How Do You Manufacture Acrylic Sheets?

At our factory, we manufacture acrylic sheets mainly through the casting process, with optional extrusion available for specific needs. Here’s a detailed overview of our production steps:

1. Raw Material Selection

We use 100% virgin PMMA (Polymethyl Methacrylate) as the raw material. No recycled materials are added, ensuring excellent optical clarity, strength, and long-term weather resistance.

2. Casting Process (Main Production Method)

Our acrylic sheets are predominantly produced through bulk polymerization casting, which involves the following steps:

Monomer Preparation: High-purity MMA (methyl methacrylate) monomer is mixed with necessary additives like UV stabilizers and colorants if needed.

Molding: The liquid monomer is poured into a mold formed by two pieces of highly polished glass plates separated by a gasket to define sheet thickness.

Polymerization: The filled molds are placed into an oven where controlled heating initiates polymerization, turning the liquid into a solid sheet.

Curing: The sheets are slowly cooled to remove internal stresses, ensuring maximum flatness and durability.

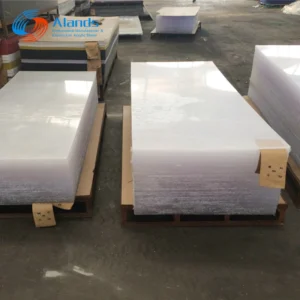

Demolding: After curing, the glass plates are removed, and the solidified acrylic sheets are separated.

Trimming and Surface Finishing: Edges are trimmed to exact sizes, and surface quality is inspected. Optional surface treatments like matte finish, frosted texture, or mirror coating can be applied upon request.

3. Extrusion Process (Optional for Fabrication Grades)

For customers requiring acrylic sheets for secondary processing (such as vacuum forming or CNC machining), we also offer extruded acrylic sheets:

PMMA pellets are melted and extruded through a flat die under high precision control.

The extruded sheet passes through rollers to achieve desired thickness and smoothness.

This method is faster and cost-effective but typically offers lower optical quality compared to cast sheets.

4. Quality Control

Every batch of acrylic sheets undergoes strict quality inspections, including:

Thickness uniformity measurement

Light transmittance testing

Surface flatness inspection

Impact resistance testing

Only products that meet our standards are packed and shipped.

5. Customization and Delivery

We support full customization in:

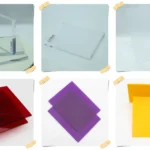

Colors (clear, colored, fluorescent, opaque)

Sizes (standard sheets or customized dimensions)

Thicknesses (ranging from 1mm to 50mm or more)

Surface finishing (glossy, matte, frosted, mirror, anti-scratch)

Our large production capacity and well-managed inventory allow us to ensure fast delivery and stable long-term supply to global customers.

Conclusion

In short, our acrylic sheets are mainly manufactured using the casting process with 100% virgin material, delivering superior optical clarity, durability, and customization flexibility. We are committed to providing high-quality products and professional service to meet various industry demands.