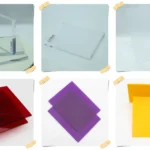

Acrylic Sheet Shipment for Indonesia with Custom Packing Service

How We Fulfilled This Acrylic Sheet Order Based on the Customer’s Shipping Requirements

In acrylic sheet export business, many customers are not only concerned about production capability, but more importantly about one question:

“Can you really follow my shipping and packing requirements?”

This acrylic sheet order shipped to Indonesia is a clear example of how we work strictly based on customer instructions. What you see in the photos is not a standard shipment, but the final result after all customer requirements were confirmed and executed step by step.

1. Customer Requirement: Acrylic Sheets Must Arrive in Original Factory Condition

During order confirmation, the customer clearly stated that:

The acrylic sheets would be used for further processing

Sheets must arrive flat and undamaged

No surface scratches caused by transportation were acceptable

The sheets should be ready for direct storage or machining after arrival

This meant that a normal or simplified export packing method could not be used.

2. Understanding the Customer’s Actual Usage Before Shipping

Before arranging packing, we first confirmed the customer’s application:

Full-size acrylic sheets

Secondary processing after arrival

High requirements for flatness and surface condition

Based on this, we defined one internal principle:

The goal of shipment is not just arrival, but arrival in usable condition.

3. Acrylic Sheet Packing and Shipping Executed According to Customer Requirements

Acrylic Sheet Preparation

All acrylic sheets retained their original protective film

Sheets were stacked evenly to avoid pressure concentration

Final inspection was conducted before packing to ensure stable condition

High-Standard Wooden Pallet Packing

As shown in the photos, the acrylic sheets were:

Placed flat on customized wooden pallets

Supported evenly at the bottom to prevent bending during long-distance transport

Packed in a way suitable for forklift handling and full container loading

This pallet structure was confirmed with the customer before execution.

Full External Protection

According to the customer’s request, the entire pallet was:

Fully covered for protection

Designed to reduce the impact of moisture, dust, and friction during sea transportation

Prepared to maintain stable condition when unpacked at destination

Reinforcement for Transport Safety

Multiple packing straps were used to fix the load firmly

Acrylic sheets, wooden pallets, and outer protection were secured as one unit

This minimized movement and risk during loading, unloading, and transportation

The photos reflect the final condition after all reinforcement steps were completed.

4. The Key of This Order Was Execution, Not Just Shipment

For this order, we did not use a default packing solution. Instead:

The customer provided clear requirements

We broke those requirements into practical steps

Each step was executed after confirmation

Only then was the shipment arranged

What the customer received was not a promise, but a visible and verifiable result.

5. More Than Acrylic Sheets: A Reliable Service Process

This acrylic sheet shipment represents more than just the product itself. It demonstrates:

Our understanding of customer needs

Our respect for customer standards

Our ability to implement requirements accurately

For us, shipment completion is not the final goal.

True delivery is achieved when the customer can unpack the sheets at the destination with confidence and use them immediately.