4x8 Black Perspex Sheet – High Quality Cast Acrylic Sheet

Premium 4×8 black Perspex cast acrylic sheet. UV-resistant, durable, glossy finish. Easy to cut and shape—perfect for signage, displays, and DIY. Custom sizes available. Inquire now!

Brand: alands

Origin: Jinan, Shandong, China

Product type: 4×8 Black Perspex Sheet

Routine size (mm): 1224*2240 or customize

Customization : size, color, thickness, style

MOQ: 1000kg (1ton)

| Thick Size/m | 2mm | 3mm | 4mm | 5mm | 8mm | 10mm | 20mm | 25mm |

|---|---|---|---|---|---|---|---|---|

| 1.25×2.45 | 7.40kg | 11.03kg | 14.70kg | 18.38kg | 29.40kg | 36.75kg | 73.50kg | 91.88kg |

| 1.25×1.85 | 5.60kg | 8.32kg | 11.10kg | 13.80kg | 22.20kg | 27.75kg | 55.50kg | 69.38kg |

| 1.85×2.45 | 16.32kg | 21.76kg | 27.20kg | 43.51kg | 54.39kg | 108.78kg | 135.98kg | |

| 1.50×2.10 | 11.34kg | 15.12kg | 18.90kg | 30.24kg | 37.80kg | 75.60kg | 94.50kg | |

| 1.60×2.20 | 12.67kg | 16.90kg | 21.12kg | 33.79kg | 42.24kg | 84.48kg | 105.60kg | |

| 1.60×2.60 | 14.98kg | 19.97kg | 24.96kg | 39.94kg | 49.92kg | 99.84kg | 124.80kg | |

| 2.05×3.05 | 22.51kg | 30.01kg | 37.52kg | 60.02kg | 75.03kg | 150.05kg | 187.56kg |

4×8 Black Perspex Sheet – High Quality Cast Acrylic Panel

Product Description

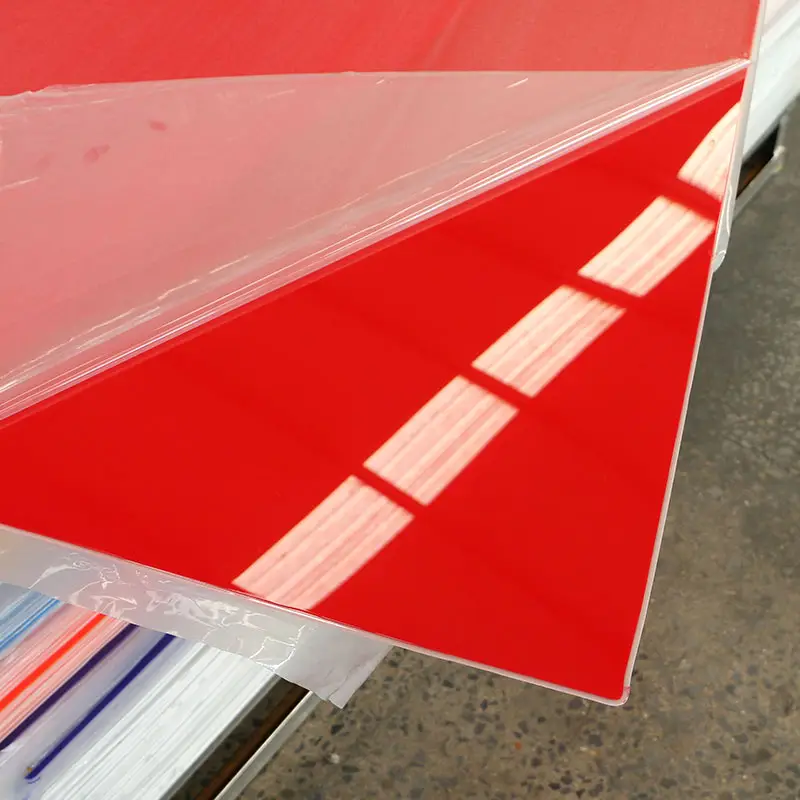

The 4×8 black Perspex sheet is a high-performance cast acrylic panel with a sleek, deep black appearance. Available in both glossy and matte finishes, it combines excellent weather resistance, strength, and a professional look. Widely used across signage, architecture, retail, and industrial sectors, it offers a lightweight and durable alternative to traditional materials like glass or metal.

Specifications & Dimensions

Standard Size: 4ft x 8ft (1220mm x 2440mm)

Thickness Range: 1mm to 30mm

Color: Opaque black (custom tones available)

Material: 100% virgin PMMA (cast acrylic)

Surface Finish: Glossy / Matte / Frosted (optional)

Weight: Approximately 7.4kg to 100kg per sheet, depending on thickness

Protective Film Options: PE protective film (default), Kraft paper (available on request)

Common Applications

The black Perspex sheet is a versatile material suitable for a wide variety of uses, including:

Signage and illuminated logo panels

Wall cladding for interior and exterior environments

Store fixtures, shelving, and product displays

Exhibition stands and promotional booths

Decorative panels for furniture or ceilings

Automotive trims, dashboards, and covers

Enclosures for machinery or electronics

Light-blocking applications in LED or display panels

Architectural models and prototypes

Frames, nameplates, and craft projects

Food display covers (for dry zones)

How to Cut Black Perspex Sheets

Perspex (acrylic) sheets can be cut using several methods depending on the tools available:

Laser cutting is the cleanest option, especially for intricate or curved shapes.

CNC routing is recommended for precision and thicker sheets.

Table saws or circular saws with fine-toothed blades are ideal for straight, clean cuts.

Scoring knives can be used for sheets thinner than 3mm.

For laser applications, kraft paper masking is preferred to reduce burn marks. Always wear protective equipment during cutting.

Customization at Alands Plastic Co., Ltd.

Alands offers full customization services for black Perspex sheets:

Color Options:

Solid black, glossy black, matte black, jet black, and smoky black

Light transmission levels can be adjusted (0%, 10%, 30%)

Size Options:

Standard 4×8 feet

Oversize sheets up to 2100mm x 3100mm

Cut-to-size services based on your project needs

Thickness Range:

From 1mm to 50mm

Precise tolerance control for technical applications

Masking Film:

Choose between PE protective film or kraft paper masking

Custom logo or print on the masking film is available

Packaging & Branding:

Pallet packing, export cartons, and branded protective film

OEM and private label options available upon request

To request a quote or discuss a custom order, email our team at info@alandsplastic.com.

Frequently Asked Questions (FAQ)

Q1: Is this material suitable for outdoor use over long periods?

Yes, the sheet is UV-resistant and weatherproof, making it suitable for both short-term and permanent outdoor applications.

Q2: Can you provide different tones or finishes of black Perspex?

Yes, we can customize both the tone (deep black, smoky, etc.) and surface (glossy, matte, or frosted).

Q3: What is the best way to store Perspex sheets before use?

Store flat in a dry, cool area, ideally on a pallet with the protective film intact. Avoid exposure to direct sunlight or heat during storage.

Q4: Can you pre-cut sheets before delivery?

Yes, we offer pre-cut and custom sizing services, including CNC or laser cutting depending on your requirements.

Q5: How long does production take for a custom order?

Production typically takes 5–10 working days depending on order size, sheet thickness, and finish. We provide faster turnaround for urgent orders.