What is the manufacturing process of acrylic?

The Manufacturing Process of Acrylic Sheets: Cast Method at Alands Factory

At Alands Acrylic Sheet Factory in Jinan, China, we produce high-quality cast acrylic sheets using a precise and controlled process. Understanding how we create these sheets can help you appreciate their superior qualities. Here’s how we make our cast acrylic sheets at Alands:

1. Preparing the Raw Materials

We start with methyl methacrylate (MMA), a clear liquid monomer. We mix this with stabilizers and pigments to improve strength, UV resistance, and color options.

2. Pouring into Molds

We carefully pour the liquid MMA mixture into glass molds that define the sheet’s size and thickness. After pouring, we seal the molds to ensure the material spreads evenly during curing.

3. Polymerization in Ovens

We place the filled molds into temperature-controlled ovens. The MMA undergoes polymerization, transforming from liquid into solid acrylic. We control the temperature to ensure the sheets cure evenly and achieve high clarity.

4. Cooling and Mold Removal

Once the sheets cure, we cool them gradually to avoid any defects. After cooling, we carefully remove the acrylic sheets from the molds, revealing their smooth and clear surface.

5. Cutting and Finishing

We trim the sheets to the required dimensions and polish them to enhance their transparency and smoothness. If needed, we apply special finishes, such as frosting or coatings, depending on the intended use.

Why the Cast Method Is Superior

The casting method offers several key advantages:

- Outstanding Clarity: We create sheets with crystal-clear transparency, perfect for visible applications.

- Enhanced Durability: Cast acrylic is more resistant to impact and wear than other types.

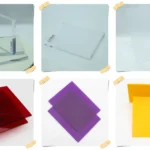

- Customization Flexibility: We can produce sheets in various thicknesses, colors, and finishes.

- Long-Term Reliability: Our acrylic sheets withstand outdoor conditions and UV exposure better than other materials.

By understanding our process, you gain insight into the benefits of choosing cast acrylic sheets for your next project. We hope this knowledge helps you make informed decisions and discover the value of high-quality acrylic.

For more details on acrylic sheet manufacturing, visit alandsacrylic-com-210518.hostingersite.com