What is the best tool to cut acrylic sheets with?

A Guide to Choosing the Best Tool for Cutting Acrylic Sheets

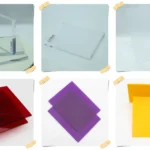

Acrylic sheets are widely used in display stands, crafts, furniture, and signage because of their lightweight nature, high transparency, and ease of processing. However, one common challenge for beginners and DIY enthusiasts is figuring out how to cut acrylic sheets quickly and cleanly. Choosing the right tool not only improves efficiency but also prevents cracking, melting, or rough edges.

Common Cutting Tools

1. Plastic Scoring Knife

Best for: Thin acrylic sheets less than 5mm.

Pros: Simple to use, inexpensive, only requires scoring several times and snapping the sheet.

Cons: Not suitable for thick sheets; edges may not be very smooth.

2. Jigsaw, Circular Saw, or Table Saw

Best for: Medium to thick sheets (over 5mm) and large-scale cutting.

Pros: Fast cutting, suitable for both straight and curved cuts.

Cons: If the blade type or speed is incorrect, it can cause melting or blackened edges.

Tip: Use a fine-tooth carbide-tipped blade and maintain medium speed to reduce friction heat.

3. Laser Cutter

Best for: High precision, intricate patterns, or batch production.

Pros: Smooth, polished edges with no need for post-processing; ideal for crafts and industrial work.

Cons: Expensive equipment; performance decreases with sheets thicker than 20mm.

4. CNC Router

Best for: Thick sheets, complex shapes, or projects requiring drilling and engraving.

Pros: High precision, suitable for complex designs.

Cons: Requires specialized software and has higher setup costs.

5. Rotary Tool / Engraving Pen

Best for: Small-scale trimming, drilling, or DIY crafts.

Pros: Flexible and precise, good for fine details.

Cons: Slow cutting speed, not efficient for large areas.

2. Helpful Cutting Tips

Keep the protective film or apply masking tape: Prevents scratches and reduces chipping during cutting.

Control speed and RPM: Avoids excessive heat buildup that causes melting.

Cooling methods: Use air or water cooling when cutting with power tools.

Post-processing: Sanding or polishing edges can restore smoothness and clarity.

3. Conclusion

For DIY and small projects: A plastic scoring knife or jigsaw works best.

For medium-to-thick sheets and straight cuts: A table saw or circular saw with a fine-tooth blade is recommended.

For high-precision crafts or professional use: A laser cutter is the top choice.

For complex designs or mass production: A CNC router is ideal.

In other words, there is no single “perfect” tool—it depends on the thickness of the sheet, the required precision, and the intended application. For most DIY enthusiasts, a scoring knife combined with a power saw will meet common needs. But if smooth edges and intricate patterns are a priority, then laser cutting is undoubtedly the best option.