What are the best acrylic sheets for laser cutting?

Best Acrylic Sheets for Laser Cutting

Cast Acrylic Sheets

Advantages: Cast acrylic is the best choice for laser cutting because it provides smoother, cleaner cut edges with minimal post-processing. It has a stable quality and won’t warp or distort significantly when cutting thicker sheets.

Applications: Ideal for projects requiring high precision and smooth edges, such as signage, display stands, engraved artwork, etc.

Recommended Thickness: Generally, cast acrylic sheets in the thickness range of 3mm to 15mm are best suited for laser cutting.

Extruded Acrylic Sheets

Advantages: Extruded acrylic is generally more affordable than cast acrylic and lighter in weight, making it suitable for simple cutting tasks. While it doesn’t produce as smooth an edge as cast acrylic, it’s still a good choice for projects where perfect edge quality is not critical.

Applications: Suitable for cost-sensitive projects such as DIY work, simple decorations, basic signage, etc.

Recommended Thickness: Sheets with thicknesses between 1mm to 6mm are ideal for laser cutting. Thicker sheets (over 6mm) may result in uneven cuts.

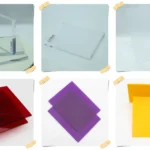

Acrylic Sheets with Special Coatings

Advantages: Acrylic sheets with coatings (e.g., frosted, glossy, or matte finishes) offer different visual effects. However, these coatings can impact the cutting quality, so adjustments need to be made based on the type of coating.

Applications: Suitable for projects that require specific visual effects or surface finishes, such as high-end display stands, decorative items, etc.

Considerations: When cutting coated acrylic, adjust the laser power according to the coating type to avoid damaging the finish.

Considerations When Choosing Acrylic Sheets for Laser Cutting

Thickness: Different thicknesses of acrylic sheets require different laser power settings. Thinner sheets (such as 3mm or 5mm) can be cut with lower power, while thicker sheets (e.g., 10mm or more) will need higher power.

Edge Quality: Cast acrylic produces smoother edges compared to extruded acrylic, which may need further smoothing or finishing.

Cutting Speed: Thicker acrylic sheets require slower cutting speeds to ensure precision and quality.

Tips

Pre-Cutting Cleaning: Ensure the acrylic sheets are clean and free of oil or dust before cutting to minimize imperfections.

Post-Processing: If customers require burr-free cuts, offer polishing or sanding services, especially for thicker acrylic sheets.