Cut to Size Acrylic Sheets: 3 Effective Methods to Cut Acrylic Easily

When working with acrylic, also known as plexiglass or PMMA, getting cut to size acrylic sheets is one of the most important steps for any project. Whether you’re creating signs, display cases, or custom panels, precise cutting ensures clean edges, accurate dimensions, and a professional finish.

There are three main ways to cut acrylic sheets: using a scoring knife, a table saw, or a laser cutter. Each method has its own advantages depending on the thickness of the sheet, the desired finish, and your tools.

1. Cutting Acrylic Sheets with a Scoring Knife

Best for: Thin acrylic sheets (under 3 mm / 1⁄8 inch)

The scoring knife method is simple, low-cost, and perfect for small DIY projects. It’s similar to cutting glass — you score the surface several times and then snap it cleanly along the line.

How to cut acrylic with a scoring knife:

Mark the cutting line with a ruler and a fine marker.

Score the acrylic several times along the line with firm, even pressure.

Clamp the sheet so the scored line is just off the edge of your table.

Snap the sheet down firmly — it should break cleanly along the scored edge.

Pros:

Inexpensive and easy to do

No power tools required

Produces straight cuts on thin sheets

Cons:

Not suitable for thick acrylic

Edges may require sanding for a smooth finish

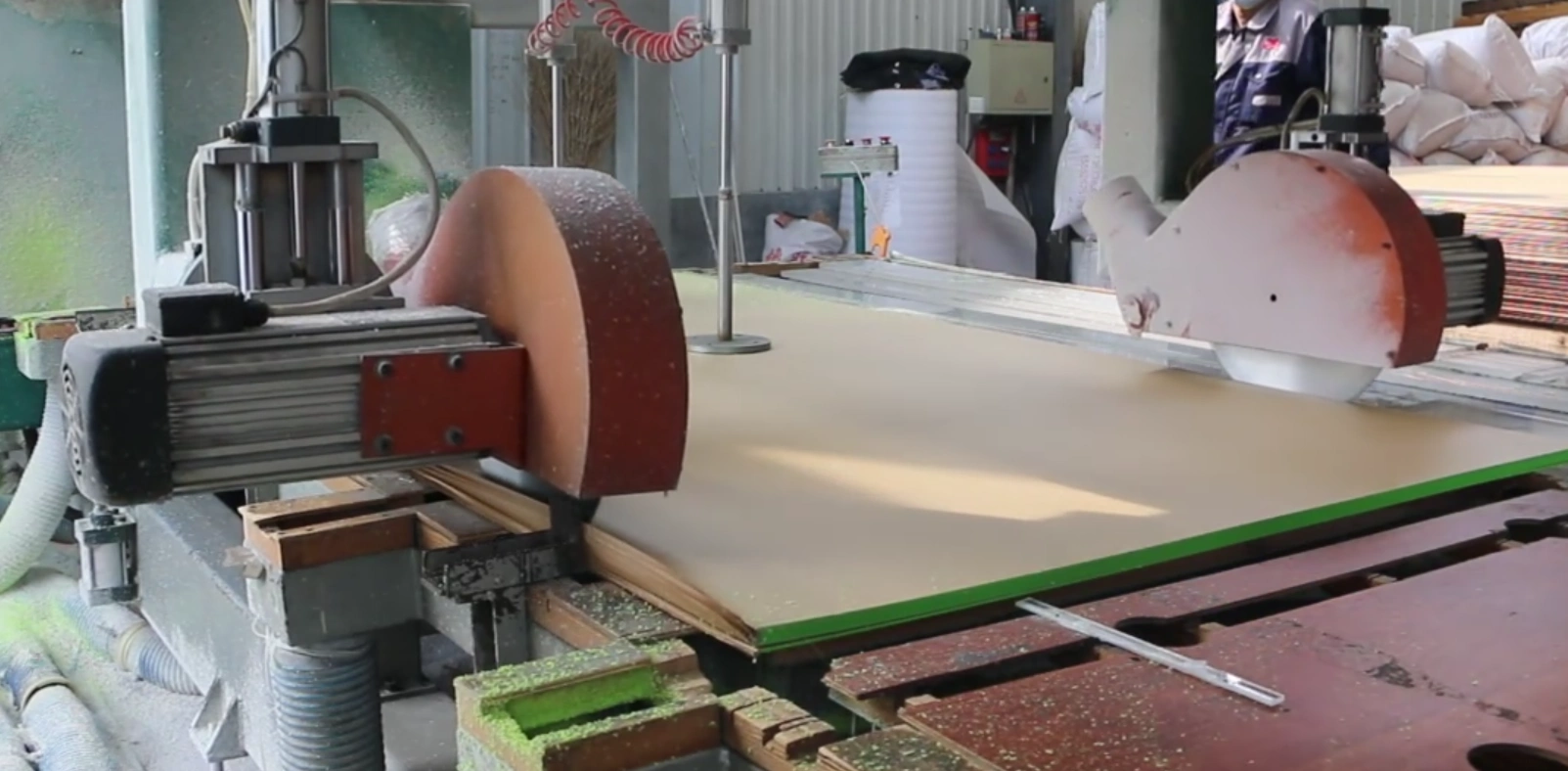

2. Cutting Acrylic Sheets with a Table Saw

Best for: Medium to thick acrylic sheets (over 3 mm)

Using a table saw is one of the fastest and most efficient ways to cut acrylic sheets to size, especially when you need multiple precise cuts.

Tips for cutting acrylic with a table saw:

Use a fine-tooth carbide-tipped blade (preferably designed for plastics).

Adjust the feed rate — too fast can cause melting or chipping.

Keep the protective film on during cutting to prevent scratches.

Support the sheet fully to avoid vibration or cracking.

Pros:

Cuts thick sheets easily

Ideal for straight, long cuts

High accuracy for repeatable sizing

Cons:

Requires a power saw and some experience

Cutting too quickly can melt or chip the acrylic edge

3. Cutting Acrylic Sheets with a Laser Cutter

Best for: Precision projects, intricate shapes, and polished edges

Laser cutting is the most advanced and accurate method for cutting acrylic. It uses a focused beam of light to melt through the material, leaving a clean, flame-polished edge with no need for sanding.

Advantages of laser cutting acrylic:

Extremely precise — perfect for custom shapes and lettering

No physical contact, reducing stress cracks

Edge comes out smooth and glossy

Works with complex or curved patterns

Drawbacks:

Requires specialized equipment

Limited to thinner sheets (usually up to 20 mm, depending on machine power)

Laser cutting is widely used in sign-making, architecture models, and retail displays where precision and aesthetics matter most.

Final Thoughts

If you’re working on small DIY projects or need a quick fix, a scoring knife is the simplest option.

For larger, thicker panels or production-level accuracy, a table saw provides efficiency and control.

But when precision and aesthetics are essential — such as signage, displays, or custom engravings — laser cutting delivers unmatched results.

So yes — you can easily get cut to size acrylic sheets using any of these three methods, depending on your needs, tools, and project scale.