How to Cut and Drill Acrylic Sheets Safely and Cleanly

Can Acrylic Sheets Be Cut and Drilled Like Wood?

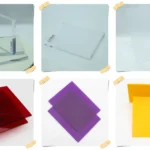

Acrylic sheets are one of the most versatile materials used in signage, home décor, DIY projects, and industrial design. But working with acrylic requires some care—you can cut and drill it, but doing it incorrectly can lead to cracks, chips, or melted edges.

The good news is: with the right tools and techniques, cutting and drilling acrylic is easy, even for beginners.

Tools You Can Use to Cut Acrylic

Acrylic is a thermoplastic, so it can be worked using many of the same tools used for wood or soft metals. The best tool depends on the thickness of the sheet and the level of precision needed.

Common Cutting Tools:

Laser Cutter – For ultra-clean, complex shapes and polished edges

Circular Saw or Table Saw – Ideal for straight cuts on thicker sheets

Jigsaw – Good for curves or rounded edges

Scoring Knife – Works on thin sheets (under 3mm), score and snap

CNC Router – For bulk or automated production jobs

When using power tools, always use blades designed for plastic—usually with fine teeth and low rake angles. This prevents chipping and minimizes heat buildup.

Drilling Acrylic Without Cracking

Acrylic can be drilled easily with standard twist drill bits, but there are some tips to avoid problems:

Use sharp, clean bits (or specialty acrylic/plastic bits)

Drill slowly and steadily—high speed can melt the acrylic

Clamp the sheet securely to prevent vibration

Place a scrap sheet underneath to prevent blow-out

Always back away gently to avoid pressure cracks

For larger holes, consider step drill bits or hole saws, used at low speeds.

Avoiding Common Mistakes

Here are some typical errors to watch out for:

| Mistake | Result | Fix |

|---|---|---|

| Using dull tools | Chipping or cracking | Use sharp blades or bits |

| Cutting too fast | Melting or warping edges | Reduce speed and feed rate |

| Drilling near edges | Cracks from stress | Keep holes at least 1.5x diameter from edge |

| Not supporting the sheet | Vibrations and uneven cuts | Use clamps and backing boards |

If you do get a rough edge, it can be polished using sandpaper (progressing from 400 to 1200 grit), a flame polisher, or plastic buffing compounds.

Choosing the Right Tools for DIY vs. Professional Work

For DIY or home improvement projects, a jigsaw, scoring knife, and drill are enough for small tasks. Just take your time and test on scrap pieces first.

For professional work, such as signage or large-scale manufacturing, use CNC routers, laser cutters, and high-speed drilling rigs with temperature control. These ensure accuracy, clean edges, and repeatability.

Working with Acrylic: Easy When Done Right

Acrylic is a friendly material—as long as it’s respected. With the right setup, you can cut and drill acrylic sheets smoothly, cleanly, and safely.

Whether you’re making display panels, signage, or custom enclosures, these techniques will help you achieve polished, professional results—no cracking, no melting, and no stress.