Expert Cold Chain Delivery of Custom Acrylic Sheets to Guatemala

Delivering Confidence: How Our Expertise Secured a Cold Chain Shipment of Acrylic Sheets to Guatemala

In the ever-evolving world of global manufacturing and export, reliability, customization, and logistics excellence are the keys to standing out. This month, our company once again proved its strength by successfully completing a complex international shipment of custom acrylic sheets to Guatemala, tailored to the client’s exact specifications and transported under cold chain conditions.

This isn’t just another delivery—it’s a demonstration of professional capability, international trust, and our commitment to quality without compromise.

Understanding the Client’s Needs: More Than Just a Product

This particular Guatemalan client operates in the retail and signage solutions sector, with strict standards for product performance. Their requirements went far beyond material supply—they needed:

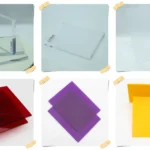

Exact sizing and coloration for visual consistency

Flawless surface finish with no warping or distortion

Delivery under stable temperature and humidity conditions

Timely and secure shipping despite seasonal climate challenges

This required a logistics approach that combines manufacturing precision with transportation science.

Our Response: Cold Chain + Precision Packaging

To meet the challenge, we delivered a complete solution:

Tailored Production

Every acrylic sheet was cut, polished, and inspected according to custom dimensions and color schemes, meeting optical and durability standards.“Frozen Instead of Dry” Logistics Strategy

To preserve the structural integrity of the sheets, especially under tropical transit conditions, we implemented cold chain transport—a method rarely applied to industrial materials but proven effective in preventing:Sheet bending from heat

Condensation-related damage

Electrostatic surface issues

Export-Grade Packaging System

Using:Double-stacked steel pallets

Moisture-resistant shrink wrap

Shock-absorbing strapping

Clearly labeled outer cartons (with batch info, size, and color)

We ensured that every item stayed in place and arrived in pristine condition.

Execution on the Ground: Trained People, Proven Process

At our loading site, the process was executed by our experienced warehouse and logistics team:

Final inspections conducted before sealing

Red industrial straps tightened and anchored within the refrigerated container

Photographic records and cargo logs prepared for the client

Real-time container temperature monitoring activated before departure

Every detail was managed with the mindset: “If we were the client, what would we expect?”

Beyond the Shipment: Building Global Confidence

This delivery not only met its timeline—it exceeded expectations. Our Guatemalan client expressed appreciation for the level of detail, from labeling to logistics tracking. In return, we earned something more valuable than a single invoice: renewed trust and an extended supply agreement.

What This Case Represents

This shipment is a reflection of our company’s global strategy:

To combine manufacturing capability with logistics intelligence

To serve clients not just with products, but with solutions

To ensure that every shipment, regardless of geography, arrives as promised—on time, on spec, and intact

As we continue to expand into Latin America and other regions, we take every delivery as a chance to show what professional export service looks like in action.