Add Can Acrylic Sheets Be Used Outdoors Long-Term? A Complete Guide to Durability, Aging, and Selection

Acrylic sheets, also known as polymethyl methacrylate (PMMA), are high-transparency thermoplastic materials widely used in signage, architecture, furniture, lighting, and display applications. One frequently asked question is: Can acrylic sheets withstand long-term outdoor exposure? Will they yellow, crack, or degrade over time?

The answer depends on several factors, including the type of acrylic, environmental conditions, and the specific application. This article explores the outdoor performance of acrylic sheets from the perspectives of material classification, weatherability, aging mechanisms, and real-world use cases.

1. Types of Acrylic Sheets and Their Impact on Durability

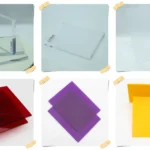

Acrylic sheets are classified based on manufacturing methods into three main types:

Extruded Acrylic

Cost-effective and easy to process, but with lower molecular density and reduced weather resistance. Suitable for indoor or short-term use.Cast Acrylic

Higher density and structural stability, with better optical and mechanical performance. More suitable for outdoor environments, typically lasting 5–8 years under normal conditions.UV-Resistant Acrylic

Formulated with ultraviolet (UV) stabilizers that significantly reduce yellowing, brittleness, and surface degradation. Designed specifically for long-term outdoor applications.

2. Performance of Acrylic Sheets in Outdoor Conditions

Strengths:

High Transparency: Even after years of sun exposure, high-grade UV-resistant acrylic maintains excellent clarity.

UV Resistance: Cast and UV-resistant sheets slow down the yellowing and embrittlement caused by UV rays.

Wide Temperature Tolerance: Operates effectively in environments ranging from -30°C to 80°C.

Corrosion Resistance: Acrylic does not rust or rot, making it suitable for humid or coastal climates.

Excellent Processability: Can be cut, drilled, bent, engraved, and combined with other materials like metals and LEDs.

Limitations:

Surface Softness: Acrylic is prone to scratching; may lose gloss in dusty or windy conditions.

Aging of Low-Grade Sheets: Non-UV-treated acrylic may yellow, craze, or crack within 1–2 years under direct sunlight.

Thermal Expansion: Acrylic expands and contracts with temperature changes; improper installation may cause warping or stress cracks.

Lower Impact Resistance than PC: Polycarbonate is preferred for structural roofing or applications requiring high impact tolerance.

3. Causes and Signs of Acrylic Aging

Acrylic degradation is mainly caused by UV radiation, oxidation, and mechanical stress. Common symptoms include:

Color Change: Yellowing or clouding of the surface.

Brittleness: Becomes rigid and prone to cracking.

Micro-Cracking: Visible stress lines, especially near edges or drilled holes.

Reduced Structural Integrity: More fragile under bending or impact.

Aging is a gradual process. Using UV-stabilized materials and proper maintenance can significantly extend the service life.

4. Typical Outdoor Applications and Selection Guide

| Application | Recommended Type | Suggested Thickness | Estimated Lifespan | Notes |

|---|---|---|---|---|

| Outdoor Light Boxes | UV-Resistant Cast | 3–5 mm | 5–8 years | Suitable for LED backlighting |

| Signboards (Storefronts) | Cast or UV Acrylic | 5–8 mm | 3–6 years | Requires firm mounting structure |

| Balcony Panels | UV-Resistant Cast | ≥6 mm | 8+ years | Reinforce with metal framing |

| Roof Canopies | Not Recommended | — | — | Use PC sheets instead |

| Temporary Booths | Extruded Acrylic | ≥3 mm | 1–2 years | Low-cost solution for short-term use |

5. Usage Tips and Maintenance Recommendations

Allow for thermal expansion in installation to avoid cracking.

Choose materials with UV stabilizers or coatings for prolonged outdoor use.

Clean regularly with soft cloth and water; avoid alcohol-based or abrasive cleaners.

Consider applying a protective film or matte finish to reduce scratching and glare.

Inspect exposed panels annually for signs of aging or damage.

6. Conclusion: Acrylic Is Suitable for Outdoor Use—If Chosen and Installed Correctly

Acrylic sheets can be used outdoors, but performance depends heavily on the material quality and installation method. Many failures are due to using indoor-grade or untreated acrylic in harsh outdoor environments.

With the right selection—particularly cast or UV-resistant acrylic—and proper installation, acrylic can last 5–10 years or more outdoors while maintaining optical clarity and structural integrity.

In signage, display, and architectural applications, acrylic remains a reliable and versatile material when correctly matched to environmental demands.

Bottom line: Not all acrylic is outdoor-grade—but when selected wisely, it performs exceptionally well under the sun.