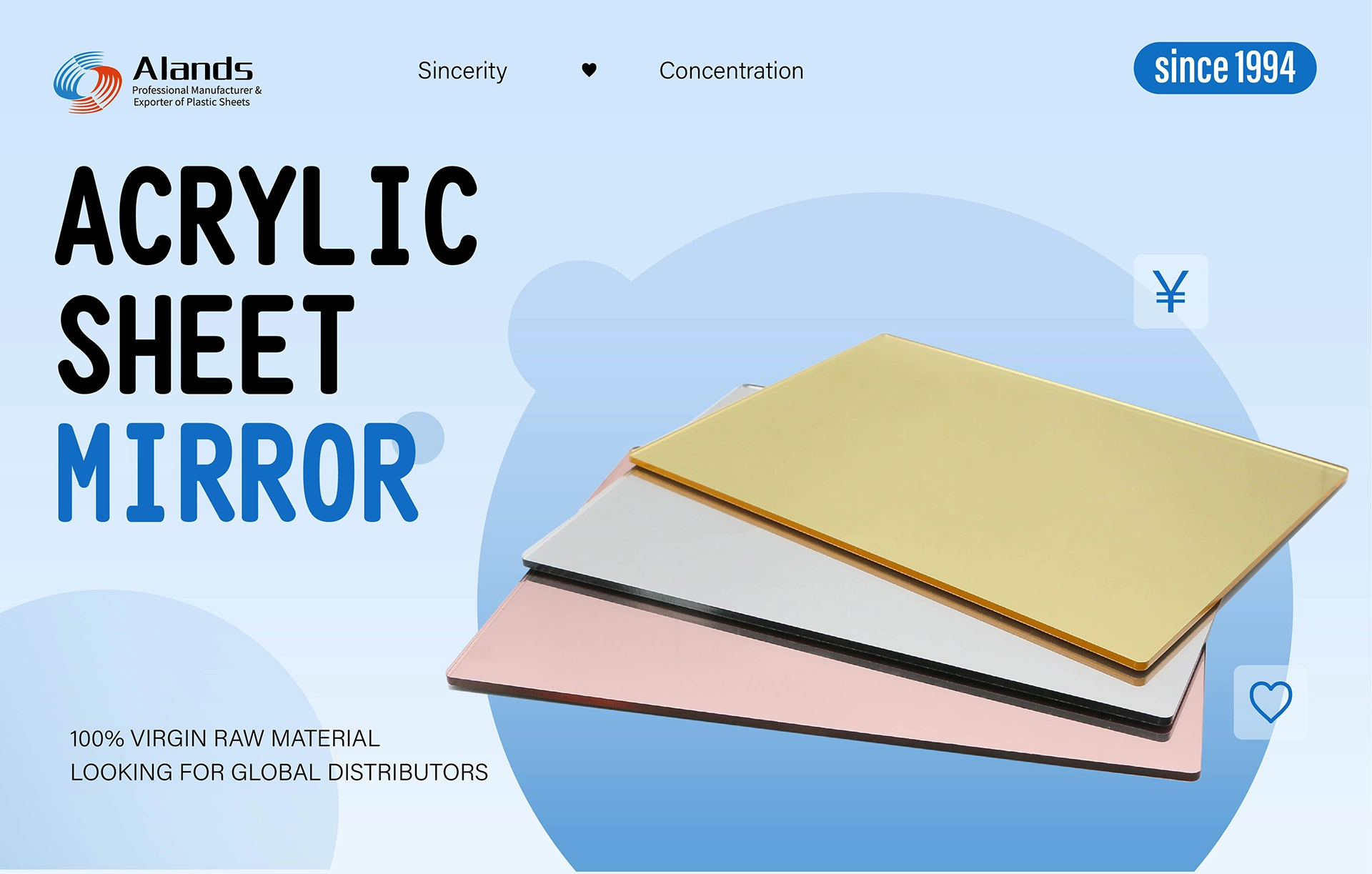

Mirror Acrylic Perspex Sheet – High-Quality Acrylic Mirror Panels

Our mirror acrylic perspex sheets are manufactured using 100% virgin PMMA to deliver exceptional clarity, durability, and processing performance. With a highly reflective surface similar to traditional glass but much lighter and stronger, these sheets are suitable for decoration, signage, crafts, retail display, and industrial applications.

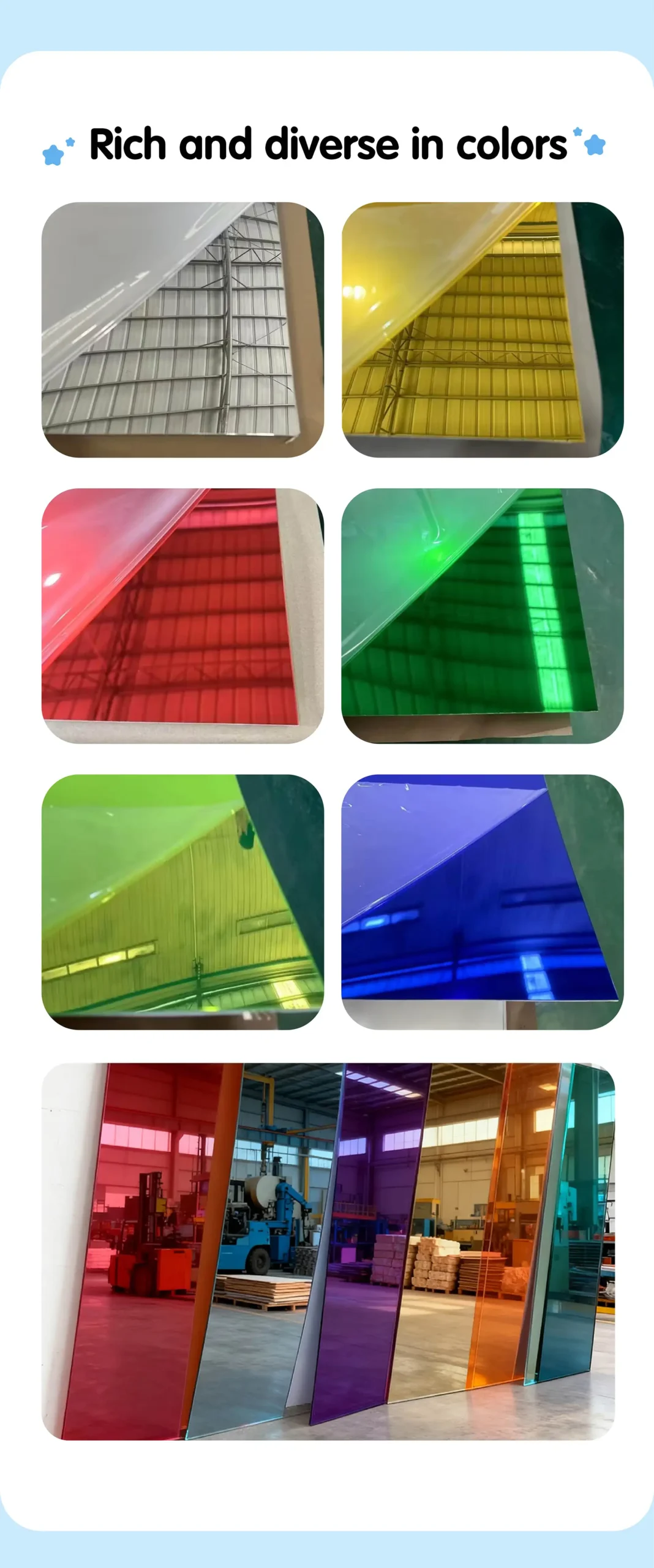

This product is available in more than thirty colors, multiple thickness options, and customized sizes to meet a wide range of project requirements.

Product Features

Mirror acrylic perspex sheets offer a bright and distortion-free reflection. They are easier to cut, engrave, bend, and shape compared with glass mirrors. The back coating is stable and scratch-resistant, ensuring long-term durability.

Advantages include:

High reflectivity with a smooth, glossy finish

Lightweight and impact-resistant

Weather-resistant and suitable for indoor and outdoor use

More than 30 color options

Easy to process with laser, CNC, or mechanical tools

Uniform mirror coating with strong adhesion

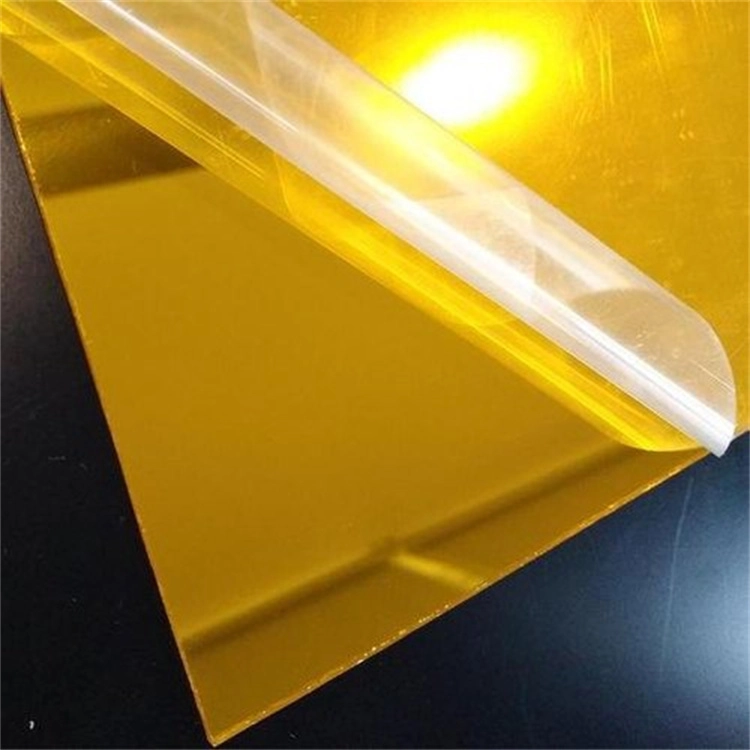

Protective PE film on both sides

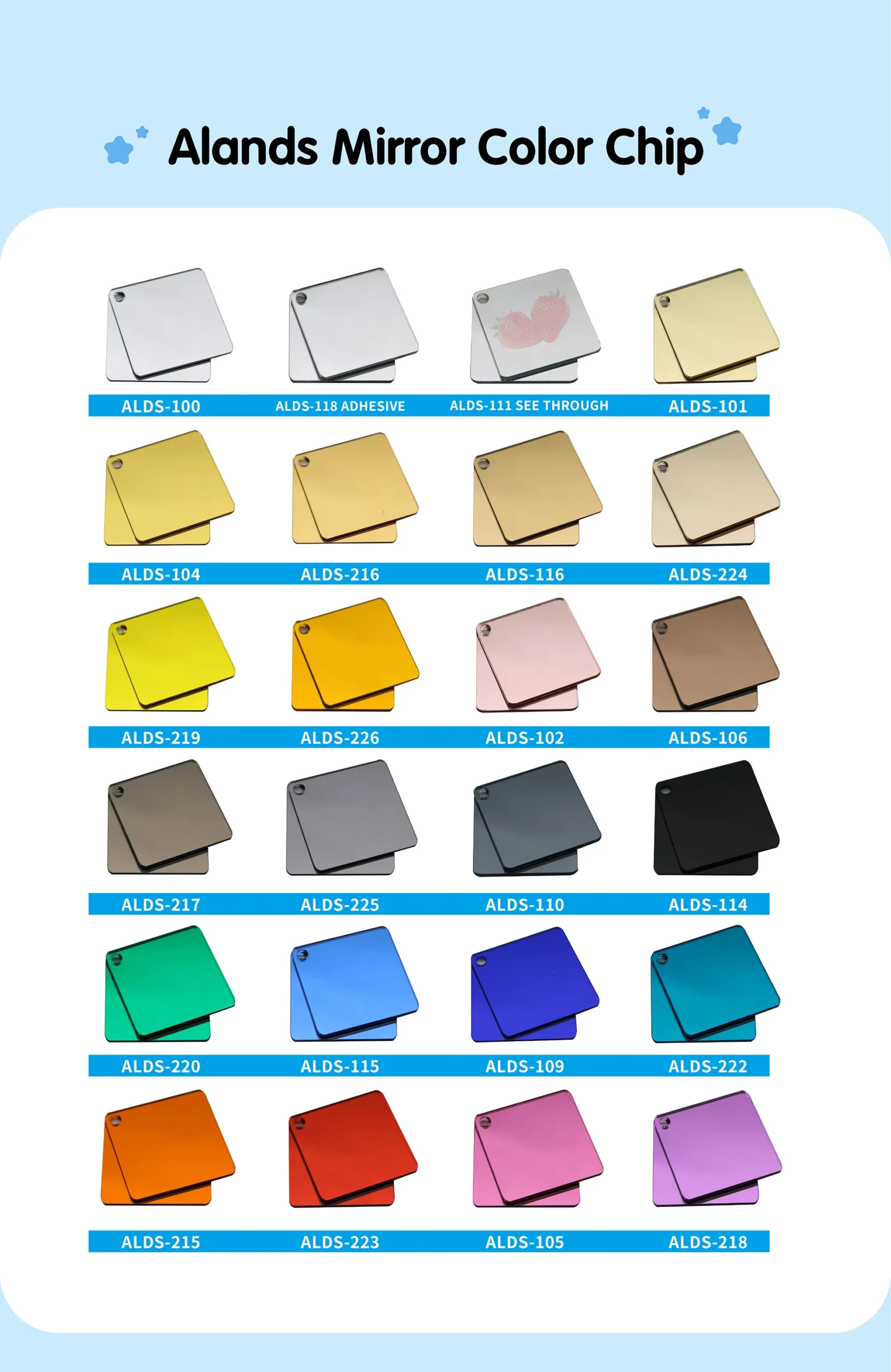

Color Options

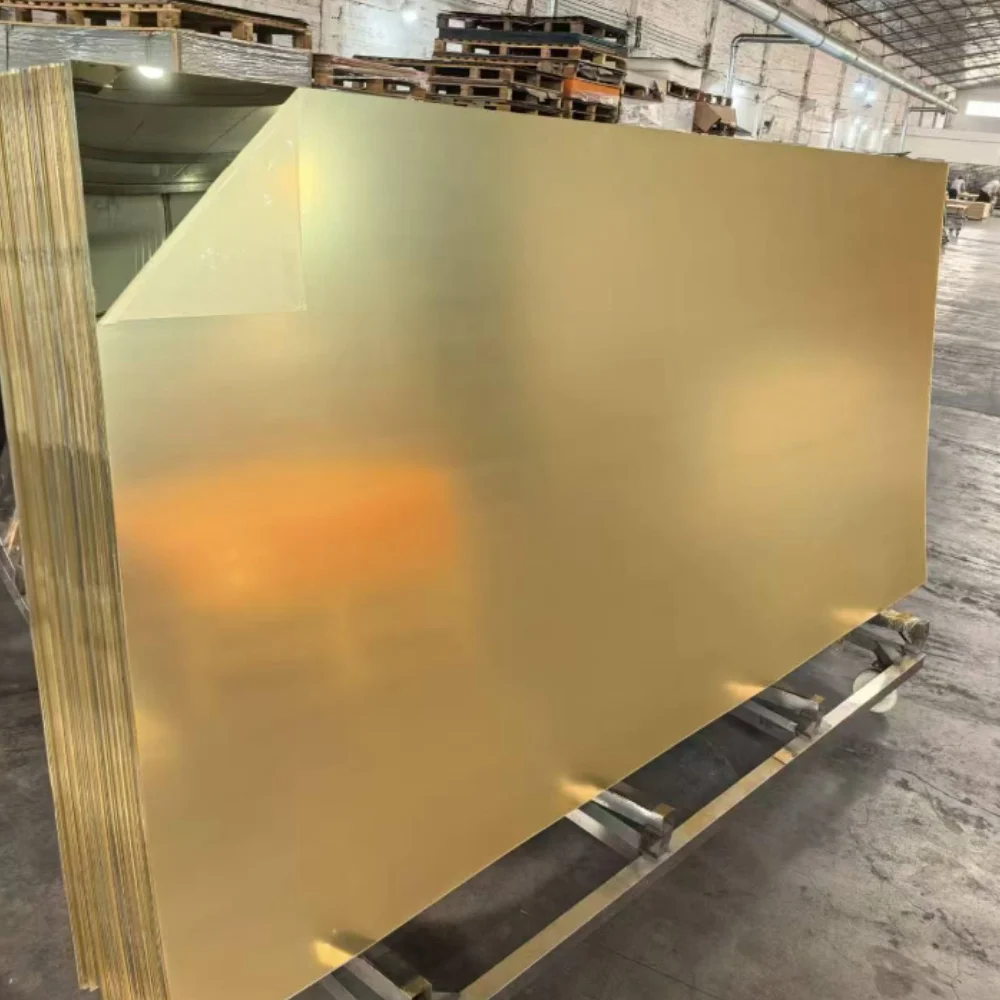

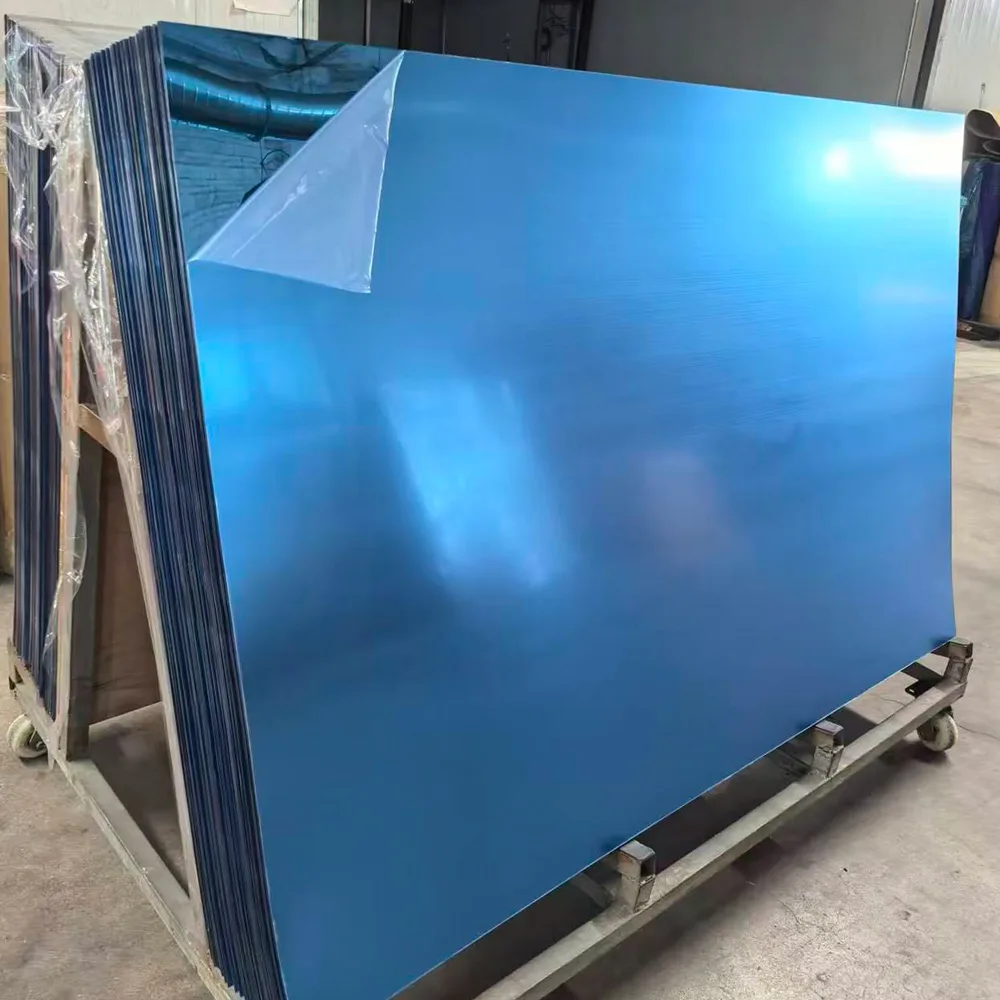

A comprehensive color system is available, including silver, gold, rose gold, bronze, grey, black, blue, red, green, purple, orange, and more.

Customized colors can also be produced upon request.

Technical Specifications

| Item | Specification |

|---|---|

| Material | 100% virgin acrylic (PMMA) |

| Thickness | 0.8mm, 1mm, 1.5mm, 1.8mm, 2mm, 2.5mm, 2.8mm, 3mm (custom 0.8–5mm) |

| Standard Sizes | 1220×1830mm / 1220×2440mm / 1020×2020mm (custom sizes available) |

| Colors | Silver, Gold, Rose Gold, Bronze, Grey, Blue, Red, Green, etc. (custom colors available) |

| Back Coating | Grey paint or self-adhesive backing |

| Surface Protection | PE protective film |

| Types | Single-sided mirror, double-sided mirror, clear mirror, two-way mirror |

| Processing Methods | Laser cutting, CNC cutting, engraving, bending |

| Delivery Time | 10–25 days |

| Application Areas | Decoration, signage, display, crafts, furniture, events, safety mirrors |

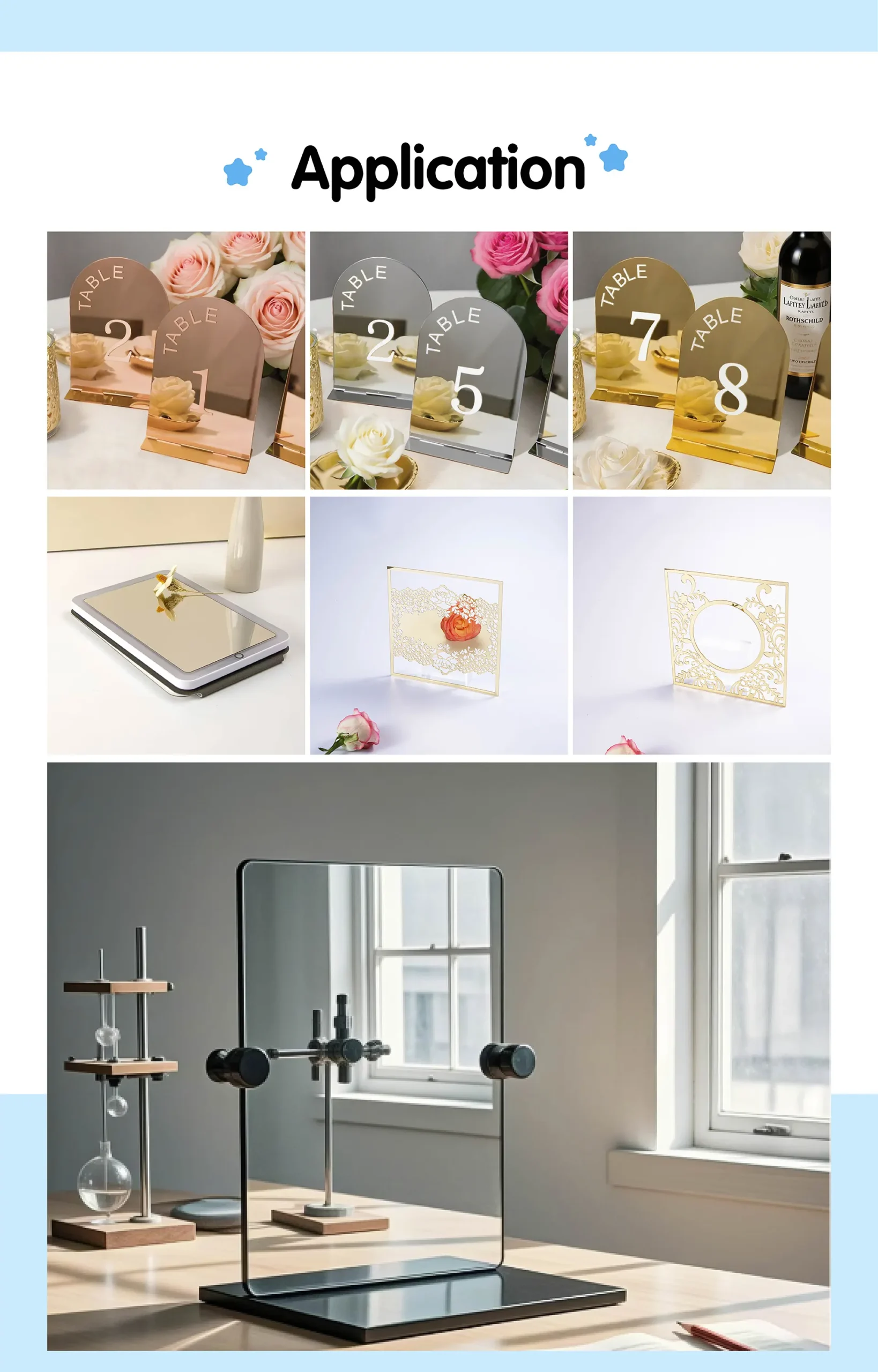

Applications

Mirror acrylic perspex sheets are suitable for a wide range of uses:

Event decorations, wedding table numbers, and display stands

Interior decoration and home art panels

Retail store signs, branding displays, and exhibition setups

Laser-cut crafts and DIY projects

Safety mirrors, children’s mirrors, and gym panels

Furniture decoration and architectural design

Production Process

Our production line covers the full process from raw material to final packaging:

Raw material feeding

Acrylic sheet extrusion

Vacuum metal plating

Mirror color coating

Quality inspection

Packaging and shipping

Every sheet is produced under strict quality control to ensure high consistency and excellent surface finish.

Packaging & Shipping

To ensure safe delivery, each sheet is protected with PE film, packed with export-standard pallets, wrapped with kraft and stretch film, and reinforced with steel straps.

We support worldwide shipping by sea, air, and express.

1. What is the maximum sheet size you can produce?

Our standard sizes are 1220×2440mm, 1220×1830mm, and 1020×2020mm. Custom sizes are available according to project requirements.

2. Can acrylic mirror sheets be laser cut?

Yes. Mirror acrylic perspex sheets can be easily laser cut, CNC routed, engraved, drilled, and shaped. For best results, keep the protective film on during processing.

3. Do you offer customized colors?

Yes. We support over 30 standard colors and can produce custom colors according to your sample or Pantone number.

4. Will the mirror coating peel or scratch easily?

No. Our mirror coating is made with high-adhesion vacuum plating and a durable back coating. It is resistant to peeling and designed for long-term use.