Black Acrylic Sheet Usage Guide

Black Acrylic Sheet Usage Guide: 8 Key Aspects You Should Know

Black acrylic sheet, known for its bold appearance and practical properties, is widely used in signage, displays, interior design, and protective installations. This guide explores eight essential aspects of working with black acrylic, helping you make better decisions in selection, fabrication, and maintenance.

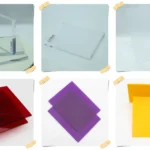

1. Black Acrylic Sheet Appearance and Surface Texture

The surface finish of a black acrylic sheet—whether glossy or matte—delivers a strong visual presence. Glossy sheets reflect light like glass, ideal for high-end branding walls or tech displays. Matte versions reduce reflections and fingerprints, often used for furniture, exhibition panels, or signage backdrops. This deep black material adds contrast and visual focus, making light, metal, or transparent components stand out.

2. Opaque Acrylic Light-Blocking Capabilities

As an opaque thermoplastic, black acrylic blocks nearly all visible light. This makes it highly effective for:

- Lightbox back panels, concealing LEDs and internal hardware

- Electronics covers, hiding wiring and modules

- Visual partitions, providing privacy in commercial or retail environments

By reducing light leakage and reflection, opaque acrylic enhances clarity in illuminated signage and digital displays.

3. Black Acrylic Panel Machinability and Fabrication

Black acrylic panels are thermoplastics, meaning they can be reshaped when heated and are easy to cut, bend, drill, and glue. Common fabrication methods include:

- Laser cutting for smooth, flame-polished edges

- CNC milling for custom shapes and engravings

- Heat bending to form curves or angles

- Solvent welding (e.g., with methylene chloride) for near-invisible seams

To avoid cracking or internal stress, always pre-drill slowly with plastic-compatible tools.

4. Black Acrylic Sheet Weather Resistance and Longevity

This material performs well outdoors thanks to UV-resistant black pigments and the stable nature of PMMA. Over time, black acrylic resists fading, yellowing, and cracking—making it ideal for:

- Outdoor signage

- Facade detailing

- Wayfinding systems

It remains stable between -20°C and 80°C, with minimal deformation from heat or cold.

5. Black Acrylic Applications Across Industries

You’ll find black acrylic used in a wide range of scenarios, including:

- Signage: Channel letter backplates, logo panels, edge lighting

- Display fixtures: Jewelry bases, electronics stands, museum props

- Interior design: Accent walls, tabletops, partition inserts

- Protective uses: Machinery shields, safety covers

- Art & fabrication: Custom installations, sculptural support bases

The material’s combination of elegance and utility makes it a designer favorite.

6. Black Acrylic Sheet Strength and Impact Resistance

While lighter than glass, black acrylic offers 5–8 times more impact strength at the same thickness. It breaks into dull-edged pieces, reducing injury risk.

- Sheets 8mm or thicker can be used in light load-bearing or protective structures

- For industrial or public settings, framed edges and thicker panels improve safety

Although it’s not as tough as polycarbonate, it’s ideal for most mid-strength applications.

7. Black Acrylic Panel Cleaning and Maintenance

Dark acrylic shows dust and fingerprints more easily than lighter materials. To keep it clean and sharp:

- Use microfiber cloths for daily dusting

- Clean with diluted neutral soap and warm water

- Avoid alcohol, acetone, or abrasive pads

Minor surface scratches can be restored with wet sanding and polishing paste. For displays or furniture, using protective films during transport and installation is recommended.

8. Black Acrylic Sheet Thickness Selection Guide

Choosing the right thickness depends on your use case:

| Thickness | Typical Use | Notes |

|---|---|---|

| 2–3 mm | Lightbox covers, product windows | Very lightweight, needs flat backing support |

| 4–6 mm | Signs, shelf surfaces | Most versatile range |

| 8–10 mm | Dividers, panels requiring strength | Can handle mild pressure or impact |

| 12+ mm | Furniture, large freestanding structures | Heavy and sturdy, best for industrial builds |

Cast acrylic is preferred for higher quality results in bending and engraving. Extruded acrylic may be suitable for cost-sensitive or less complex jobs.

Final Overview

Whether referred to as a black acrylic sheet, dark PMMA panel, or opaque acrylic, this material offers a rare mix of aesthetics and function. With the right approach to fabrication, care, and application, it serves reliably in creative, commercial, and industrial environments alike.